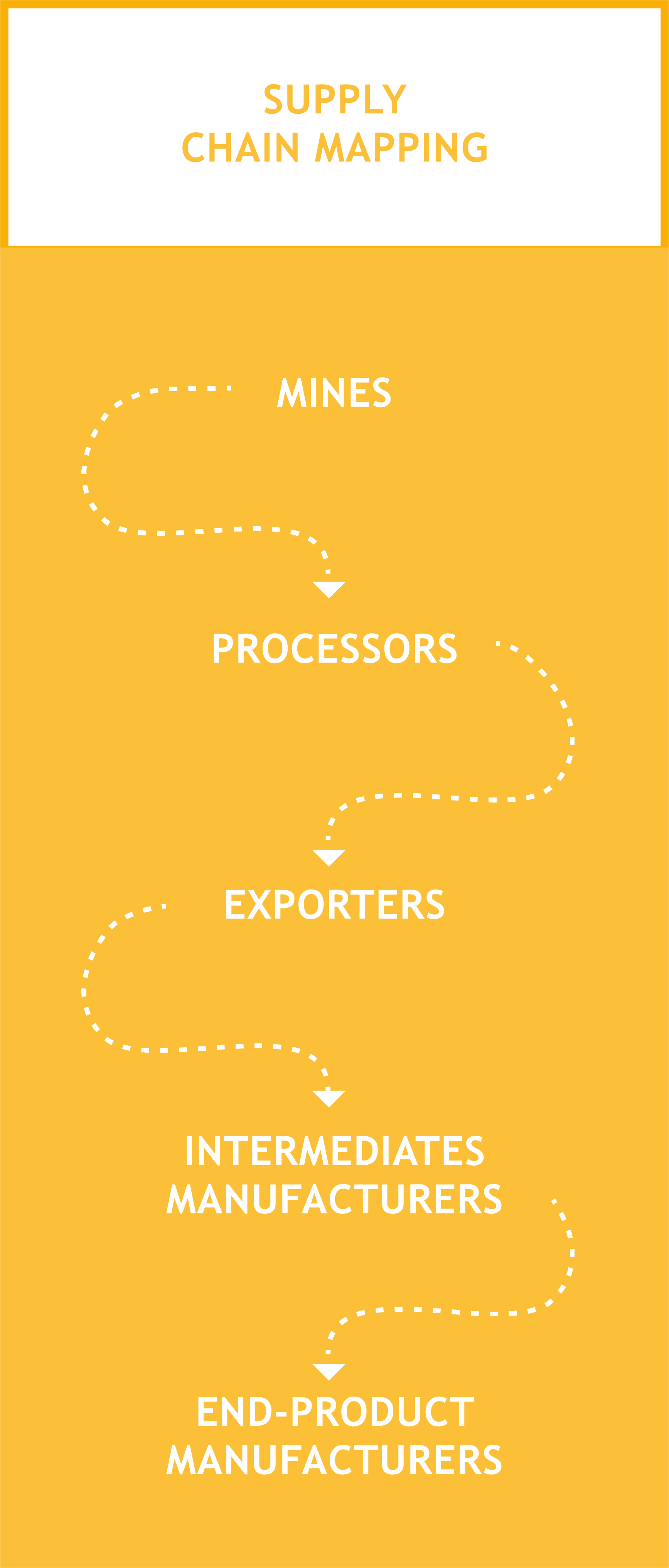

The Supply Chain Mapping and Workplace Standards program pillar is designed to secure and improve workplace conditions in the supply chain for mica collection and processing. First, each RMI member traces the mica in its products and maps the participants in its supply chain back to the processors and mines which supplied the mica. Second, each participant in the member’s supply chain is required to adopt or support adoption within its own supply chain of workplace standards that encompass environmental, health, safety, legal, economic and fair labor practices, including a prohibition on the use of child labor.

RMI members adhere to the principle of supply chain transparency. They agree to support upstream members of their supply chain, including mines and processors, to adopt workplace standards.

To identify the mines and processors, members agree to map their supply chains. Members range from global manufacturers of end-products, such as electronics and cosmetics that use mica and manufacturers of intermediates, such as pigments, paints and coatings, to mica exporters, processors and mine operators in India.

At the inception of the mapping protocol program in 2018, RMI members represented 30 percent of India’s mica exports by volume and 37 percent of exports by volume originating from the states of Bihar and Jharkhand.

The scope of the initial mapping exercise ensured that the program would be relevant to the jurisdictions in India that presented the greatest challenges to developing a responsible supply chain free of child labor. In 2019, member volumes represented 57 percent of India’s mica exports by volume and 70 percent of exports by volume originating from the states if Bihar and Jharkhand. Members agree to repeat the supply chain mapping protocol annually to keep program data and scope relevant.

| RMI members collectively represent | 57% | of mica exports from Bihar and Jahrkhand |

RMI members must request mica processors and mine operators identified through the annual mapping protocol to adopt workplace standards that will ensure good working conditions. Members further agree to support their supply chain members in their efforts to adopt the standards.

The standards include policies and practices that cover environmental management systems, occupational health and safety programs and fair labor practices which include prohibitions on child labor. Provisions of the standards incorporate requirements under Indian law as well elements of global voluntary standards or conventions such as those established by ISO (International Organization for Standardization),the International Labor Organization, and the US Occupational, Health and Safety Administration that were adapted to ensure they are compatible with local conditions. Working with local program partners, RMI’s workplace standards encompass goals in five dimensions of operations.

The workplace standards were developed in 2017 and finalized in 2019 after they were evaluated in a trial which took place during 15 months, starting the second quarter of 2018. To scale-up implementation, RMI and program partners developed training materials tailored for facility managers and workers to ensure that the standards are understood and adhered to. Training sessions, launched in May 2019, are open to members and non-members of RMI.

To support adoption of the workplace standards, when processors join RMI they must use a Compliance Self-Assessment (CSA) tool that enables them to compare current workplace practices with the requirements of the standards. The CSA tool identifies gaps between current and desired workplace practices and provides the basis for Suggestions on Improvement Areas (SIAs). The gap analysis must be completed by processors prior to joining RMI. Any changes identified in the SIAs must be implemented within one year.

All participants of RMI member supply chains must adopt the workplace standards using above mentioned resources. The workplace standards and other related resources are also available to any supply chain participant. Participation in training sessions are available to RMI members at no extra cost and also available to non-members for a modest fee. For more information about the RMI Supply Chain Mapping and Workplace Standards program, please contact us.

|  |

| RMI members collectively represent | 57% | of mica exports from Bihar and Jahrkhand |

RMI members must request mica processors and mine operators identified through the annual mapping protocol to adopt workplace standards that will ensure good working conditions. Members further agree to support their supply chain members in their efforts to adopt the standards.

The standards include policies and practices that cover environmental management systems, occupational health and safety programs and fair labor practices which include prohibitions on child labor. Provisions of the standards incorporate requirements under Indian law as well elements of global voluntary standards or conventions such as those established by ISO (International Organization for Standardization), the International Labor Organization, and the US Occupational, Health and Safety Administration that were adapted to ensure they are compatible with local conditions. Working with local program partners, RMI’s workplace standards encompass goals in five dimensions of operations.

The workplace standards were developed in 2017 and finalized in 2019 after they were evaluated in a trial which took place during 15 months, starting the second quarter of 2018. To scale-up implementation, RMI and program partners developed training materials tailored for facility managers and workers to ensure that the standards are understood and adhered to. Training sessions, launched May in 2019, are open to members and non-members of RMI.

To support adoption of the workplace standards, when processors join RMI they must use a Compliance Self-Assessment (CSA) tool that enables them to compare current workplace practices with the requirements of the standards. The CSA tool identifies gaps between current and desired workplace practices and provides the basis for Suggestions on Improvement Areas (SIAs). The gap analysis must be completed by processors prior to joining RMI. Any changes identified in the SIAs must be implemented within one year.

All participants of RMI member supply chains must adopt the workplace standards using above mentioned resources. The workplace standards and other related resources are also available to any supply chain participant. Participation in training sessions are available to RMI members at no extra cost and also available to non-members for a modest fee. For more information about the RMI Supply Chain Mapping and Workplace Standards program, please contact us.